Greywater sources in buildings include wastewater from sinks, showers, air conditioning cooling systems, condensate, swimming pools, laundry, kitchens, and toilet flushing. We offer various treatment processes tailored to different greywater types.

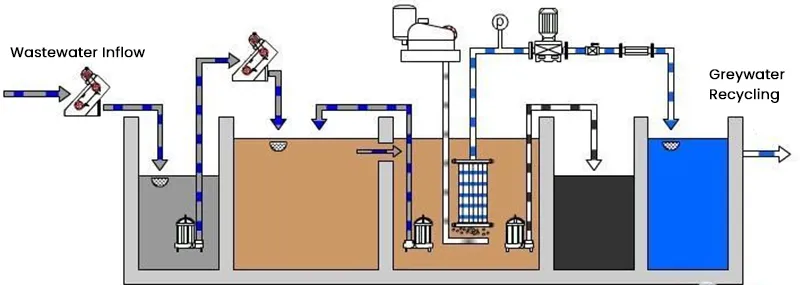

- Wastewater Inflow

- Greywater Recycling

| Raw Water Category | Process Flow | Water Usage | Installation Location | |

| High-Quality Miscellaneous Discharge Water (COD: 90~200mg/l, BOD:50~100mg/l) | Air Conditioning Condensate (COD: 90~120mg/l) | Filtration (Multi-media Filter) + Disinfection (Sodium Hypochlorite Dosing Unit and UV Disinfection Unit) | Irrigation, Car Washing, Toilet Flushing, Cooling Tower Make-up Water | Machine Room or Underground Integrated |

| Wash Basin (COD: 100~150mg/l, BOD:50~100mg/l) | Hair and Lint Strainer + Coagulation Sedimentation + Filtration + Disinfection | |||

| Shower Wastewater (COD: 150~200mg/l, BOD:50~100mg/l) | Hair Filter + Coagulation Sedimentation / A+MBR + Disinfection | |||

| Domestic Sewage (COD: 300~1000mg/l, BOD:100~600mg/l) | Toilet Sewage | Septic + A (O/A2O) + MBR + (Advanced Treatment) + Disinfection | ||

| Kitchen Sewage | Oil Separation + A (O/A2O) + MBR + (Advanced Treatment) + Disinfection | |||

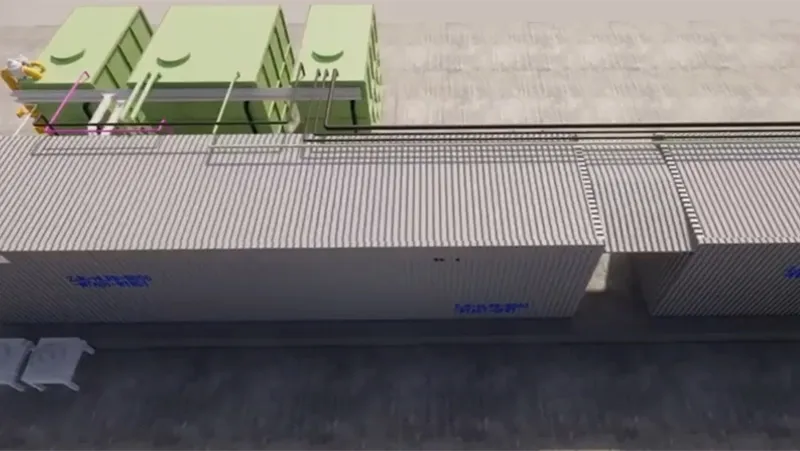

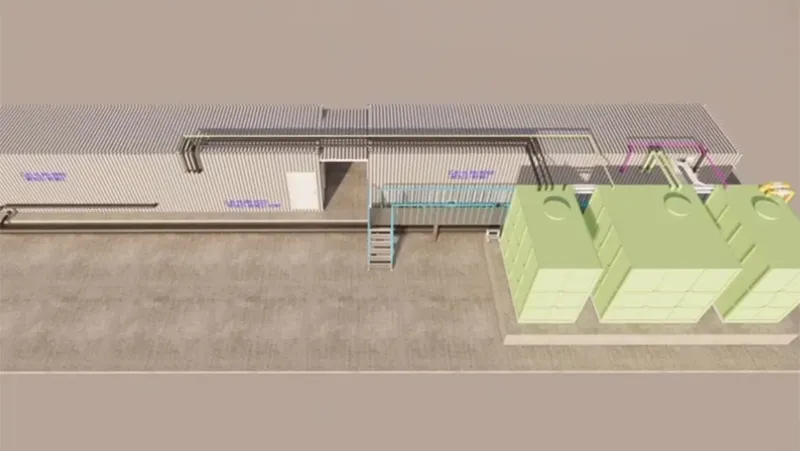

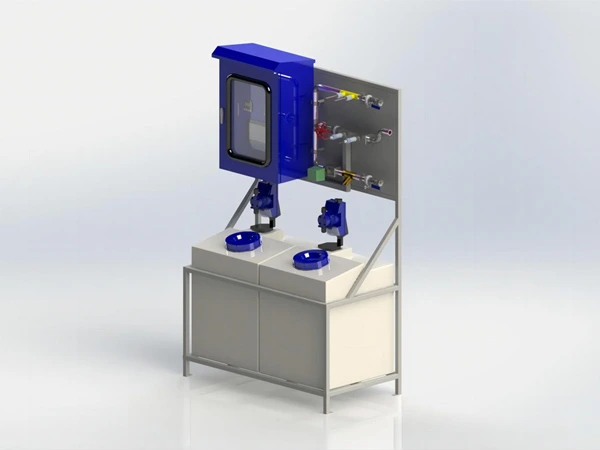

Raw Water: Domestic greywater (excluding sewage) with a total discharge of 45.6m³/day and 64.1m³/hour, basement shower drainage, and tower air conditioning condensate water with a total discharge of 35m³/day and 4.4m³/hour.

Treatment Process: The greywater first passes through mechanical screens and enters a greywater adjustment tank. From there, it is pumped to anaerobic and aerobic bioreactor tanks for biological treatment. The treated water is then processed in Membrane Bioreactor (MBR) tanks. Using suction pumps, the clean water is transferred to the greywater pump station's clean water tank. The recycled water is then pressurized and distributed through the greywater network for reuse in non-potable applications such as flushing and irrigation, ensuring efficient water utilization and sustainability in an urban environment.

- Each year, we produce 200 rainwater and greywater collection systems, 150 wastewater reuse and treatment systems, 150 water purification systems, 100 swimming pool systems, 1,400 automatic dosing systems, 700 other water treatment systems, and 30,000 tons of water treatment chemicals.

- Our strong R&D and production capabilities have earned us many accolades, including national high-tech enterprise status, recognition as a Shanghai innovative enterprise, and a top 100 private technology company in Shanghai for tax contributions.

- We manage over 100 third-party environmental pollution control facilities and provide comprehensive water treatment solutions to over 2,000 clients, including more than 128 Fortune 500 companies.